APM is a top supplier of high quality automatic screen printers, hot stamping machines and pad printers, as well as automatic assembly line, UV painting line and accessories.

All machines are built according to CE standard.

Application:

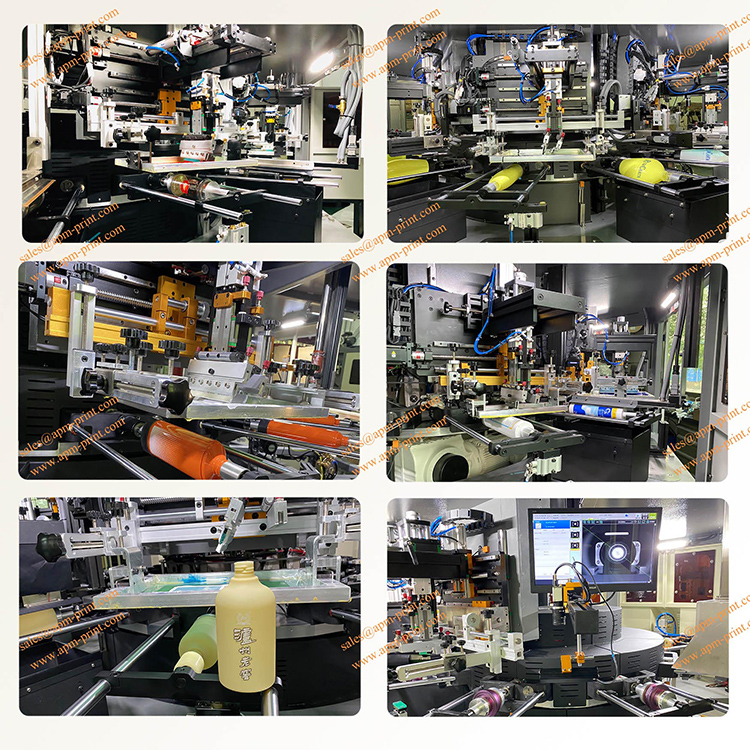

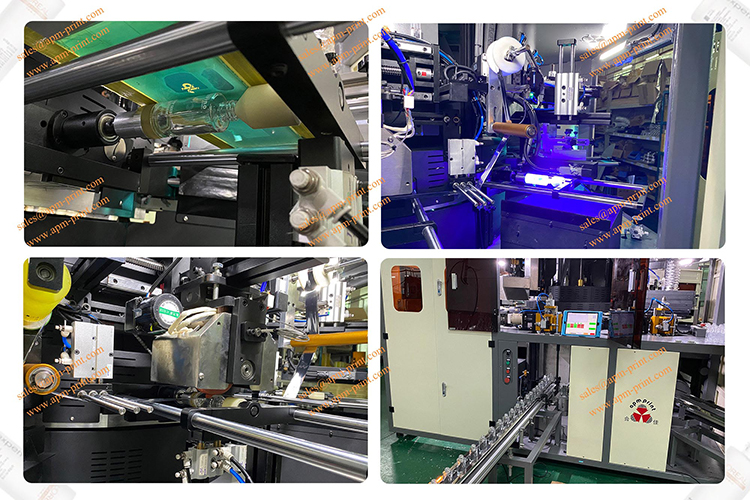

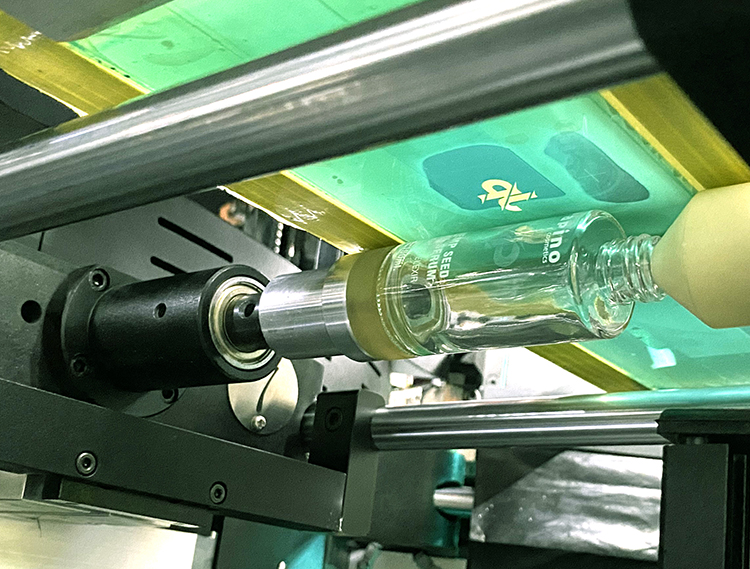

The CNC106 is designed for 2+colors decoration of all shapes (round, oval, square...) of glass/plastic bottles , cups, mugs screen printing and hot stamping at high production speeds. Mostly used for wine bottles printing. It can print any shape of containers all around in 1 print. It is suitable for glass or plastic containers printing with UV ink or LED ink. All servo driven and fast speed make the CNC106 ideal for off-line or in-line 24/7 production.

General Description:

1.Automatic loading system with multi axis servo robot.11.Well built machine house with CE standard safety design.

Options:

1. Camera vision system (CCD) to check the mold line for cylindrical bottles print, to avoid printing on the line; for cylindrical products without registration point, repeat print to be double colors.

2. New shape program upgrading through internet.

3. Second color can be replaced with hot stamping head if the first color is UV/LED print.

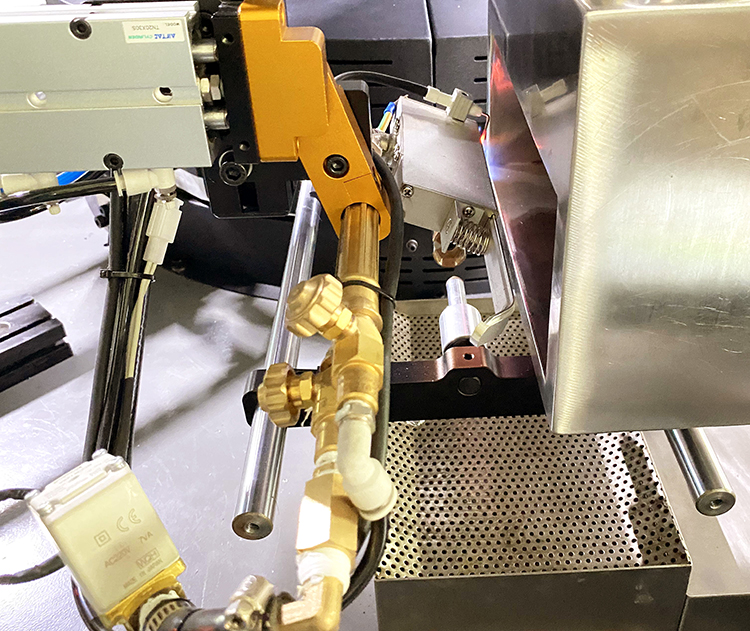

4. Can be equipped with heating system for thermo plastic ink printing for glass bottles.

5. Simplified model: SS106 for cylindrical bottles only.

6. Big auto loader for plastic bottle printing

Tech-data:

|

Parameter/Item |

CNC106 plastic/glass container printer |

|

power |

380V, 3P 50/60Hz |

|

Air consumption |

6-8bar |

|

Max Printing speed |

20-40pcs/min |

|

Max. printing Dia. |

100mm |

|

Max. printing circumstance |

250mm |

|

Printing height |

25-250mm |

|

Max. product height |

300mm |

Main part brand

|

CONTROL SYSTEMS |

YASKAWA PLC |

JAPAN |

|

TOUCH SCREEN |

WEINVIEW |

TAIWAN |

|

SERVO SYSTEMS |

YASKAWA |

JAPAN |

|

INDEX |

DEX |

TAIWAN |

|

ELECTRICAL PARTS |

OMRON/SCHNEIDER |

JAPAN/FRANCE |

|

PNEIMATIC PARTS |

SMC/AIRTAC |

JAPAN/Taiwan |

The sample picture:

| Quick Links | Hot product | Contact information |

|---|---|---|

|

|